Beile creation

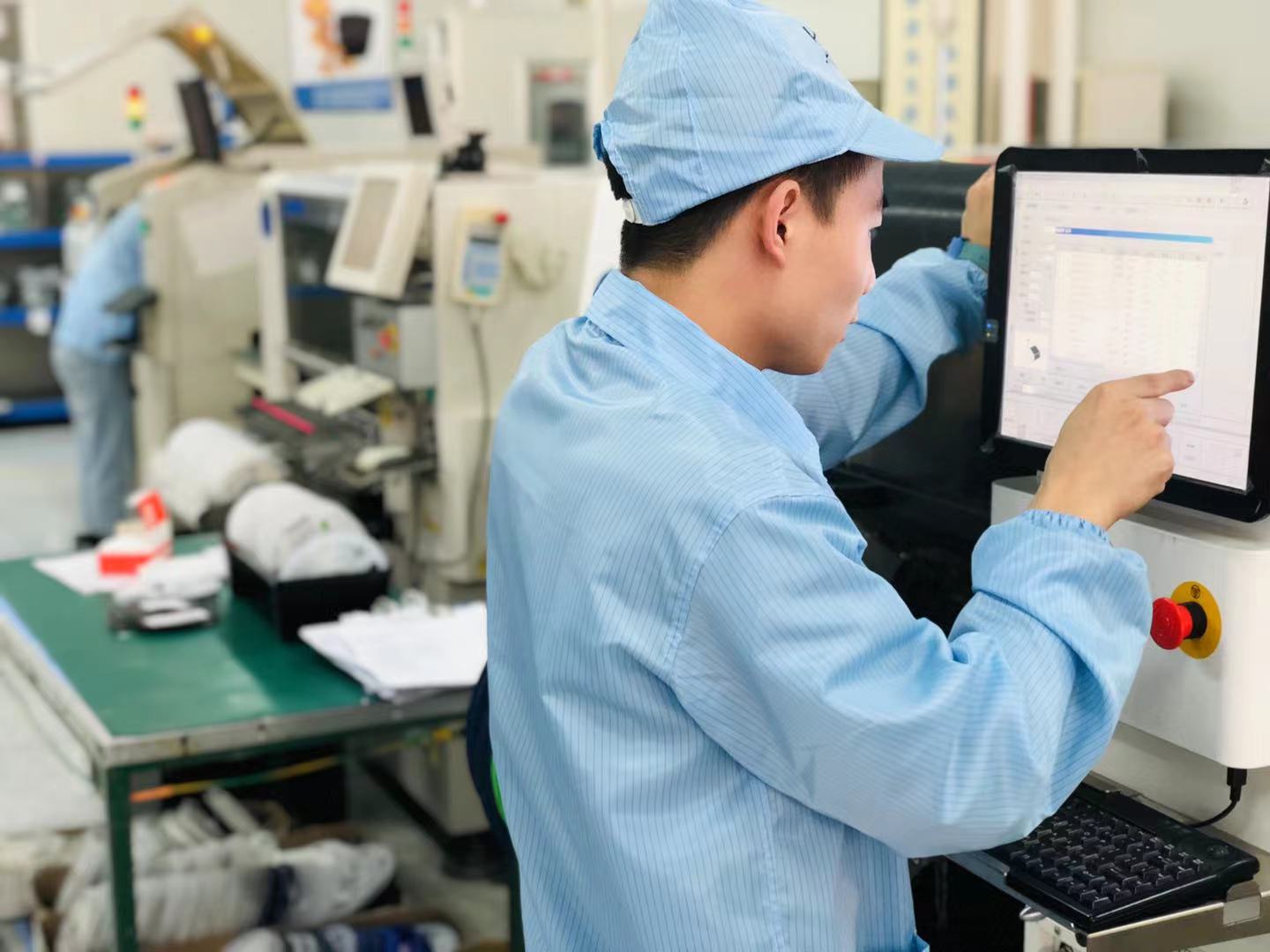

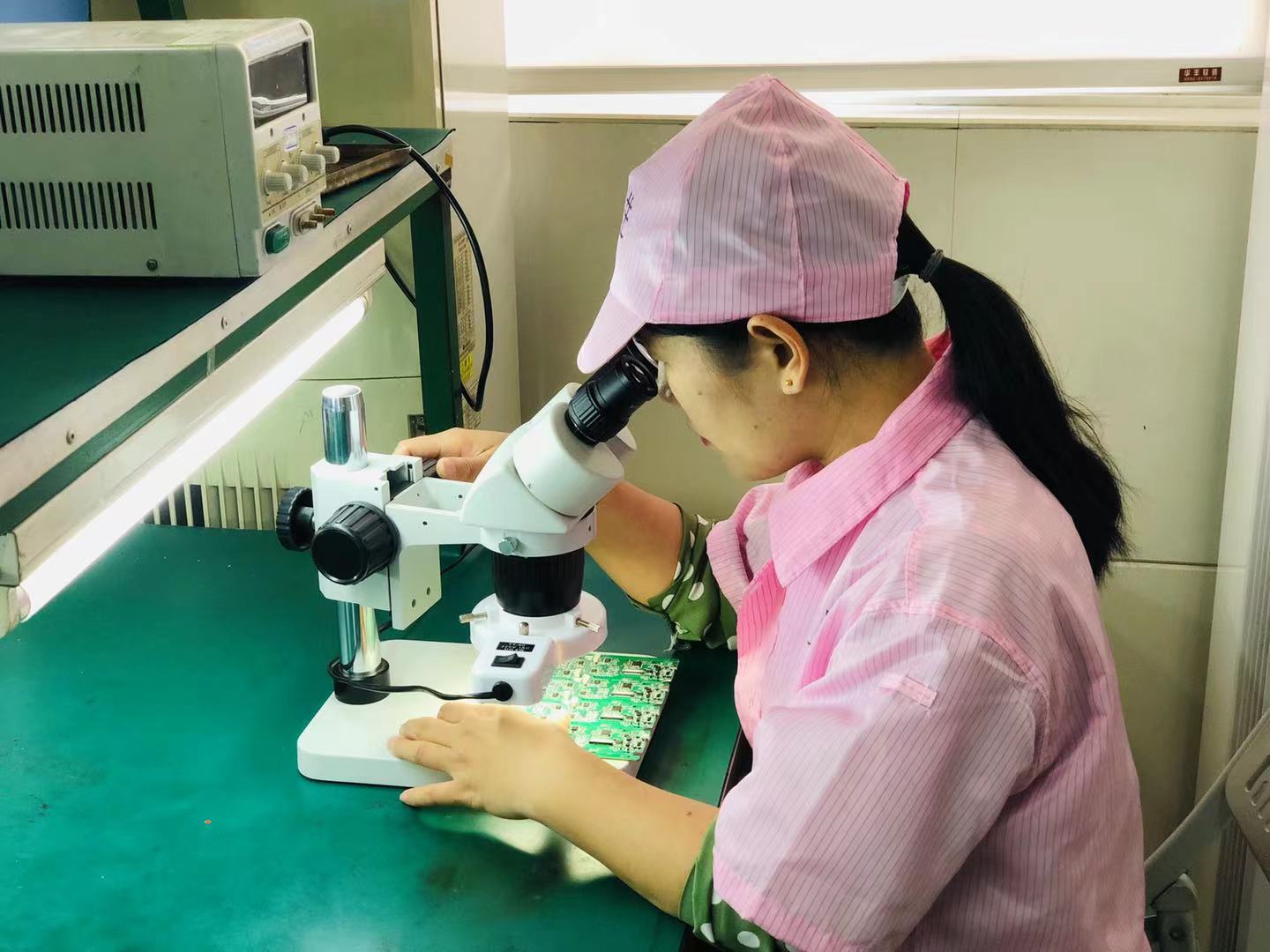

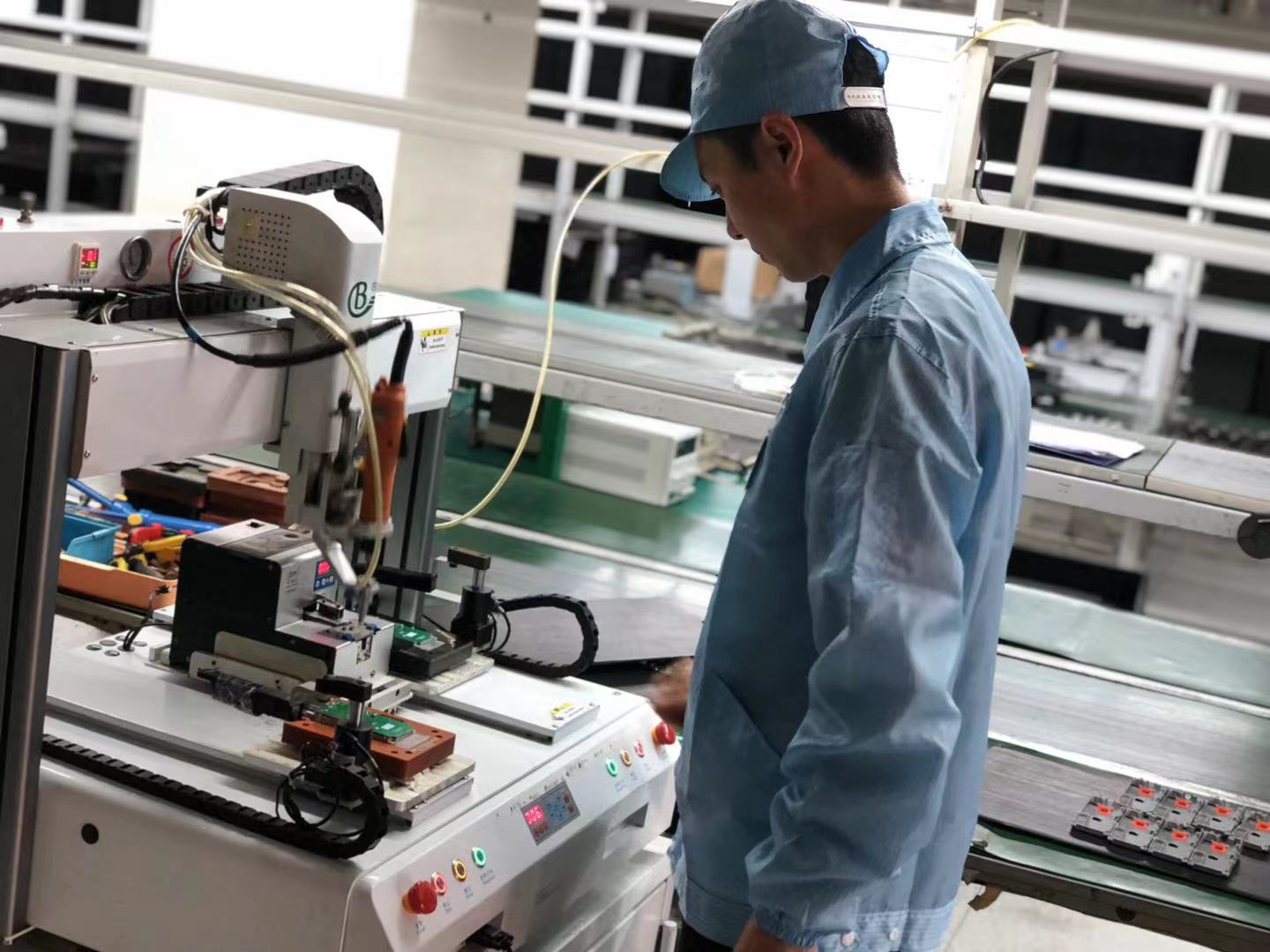

The production facilities cover an area of 5000 ㎡, owning 16 Japanese high-precision mounter production lines, Panasonic NPM-W2 and JUKI mounters,Hitachi high-precision printing machines and 10-temperature reflow ovens, ICT testers, online AOI and offline AOI inspection machines, and holding SPI 3D solder paste inspection machines, X-RAY testers, LCR testers for first sample . A variety of testing equipment and instruments can undertake 0201, 0402, 0603, 0805, 1206 and BGA, CSP and other 0.3 pitch surface mounting of various shaped parts.

Daily Production for SMT up to 10 million pieces, in addition, the company has a THT workshop and assembly workshop. The introduction of six advanced plug-in production lines and lead-free high wave, double wave soldering equipment provides customers with single-side mounting and insertion mixing or double-side mounting and insertion mixing, the daily production for THT up to 5 million pieces.

|  |  |

|  |  |